Error message

- Notice: Trying to access array offset on value of type int in element_children() (line 6569 of /home4/devan1ay/public_html/includes/common.inc).

- Notice: Trying to access array offset on value of type int in element_children() (line 6569 of /home4/devan1ay/public_html/includes/common.inc).

- Notice: Trying to access array offset on value of type int in element_children() (line 6569 of /home4/devan1ay/public_html/includes/common.inc).

- Notice: Trying to access array offset on value of type int in element_children() (line 6569 of /home4/devan1ay/public_html/includes/common.inc).

- Notice: Trying to access array offset on value of type int in element_children() (line 6569 of /home4/devan1ay/public_html/includes/common.inc).

- Notice: Trying to access array offset on value of type int in element_children() (line 6569 of /home4/devan1ay/public_html/includes/common.inc).

- Notice: Trying to access array offset on value of type int in element_children() (line 6569 of /home4/devan1ay/public_html/includes/common.inc).

- Notice: Trying to access array offset on value of type int in element_children() (line 6569 of /home4/devan1ay/public_html/includes/common.inc).

- Notice: Trying to access array offset on value of type int in element_children() (line 6569 of /home4/devan1ay/public_html/includes/common.inc).

- Notice: Trying to access array offset on value of type int in element_children() (line 6569 of /home4/devan1ay/public_html/includes/common.inc).

- Notice: Trying to access array offset on value of type int in element_children() (line 6569 of /home4/devan1ay/public_html/includes/common.inc).

- Notice: Trying to access array offset on value of type int in element_children() (line 6569 of /home4/devan1ay/public_html/includes/common.inc).

- Deprecated function: implode(): Passing glue string after array is deprecated. Swap the parameters in drupal_get_feeds() (line 394 of /home4/devan1ay/public_html/includes/common.inc).

New Technoligies in handloom / கை தறியில் புதிய தொழில்நுட்பம்

http://www.newindianexpress.com/states/kerala/IIHT-Develops-Multi-functi...

KANNUR: The Indian Institute of Handloom Technology (IIHT), Thottada, has developed a handloom with innovative design that is expected to make the sector more desirable. Called ‘Loom Cot’ or ‘Handloom Cot,’ the new devise can serve the purpose of a loom and a cot and can fit into a normal bedroom without consuming additional space. Introducing the Loom Cot, Abdul Kareem Cheleri, the executive director of IIHT, a state government institution, said that the multi-functional device would be attractive for small families with limited space and for the middle class people who look for a stylish design. “The new design is very compact and it can be easily folded into a cot once the day’s work is over,” he said. “Developed by the IIHT after a research of one-and-a-half years, the Loom Cot is ready for commercial production. Officially launched at a function the other day in Kochi, the institute has also started efforts to secure a patent for the innovative design,” Abdul Kareem Cheleri said. “The young generation is not coming forward to take up hand weaving and even the traditional weavers are quitting due to various reasons. Nevertheless, many women are still interested in handloom, but scarcity of space to install handloom deters them. Finding additional space for handloom comes in the way,’’ Abdul Kareem said. Designed as a box, the Loom Cot can comfortably sit in an average room without consuming extra space and even the middle class people would find it attractive. Moreover, the cost of setting up a traditional loom and a Loom Cot would be more or less the same, the IIHT executive director explained. “As per the initial estimation, a Loom Cot will cost around `1 lakh, almost similar to the cost of installing a traditional handloom. But if we go for commercial production, the price will come down,” he added.

“The development of Loom Cot was one of the three projects initiated by the IIHT with the aid of the state government. The research to develop a nano handloom machine and the development of software-based textile design studio are progressing. We hope to launch both of them within a year,” Abdul Kareem Cheleri said.

An exhibition of Loom Cot will be held at the IIHT, Thottada, here from September 1 to 5. The institute would provide training for people interested in the Loom Cot, the official said.

http://indianexpress.com/article/explained/explained-why-indias-handloom...

For Narendra Modi, the revival of handloom in his constituency Varanasi was a repeated and emotive campaign promise. Last month, days before the government completed a year in office, a delegation of designers led by BJP politician Shaina NC met with Textiles Minister Santosh Kumar Gangwar. Among the initiatives proposed at the meeting were setting up dyeing centres, providing subsidised yarn, a campaign for handloom along the lines of Incredible India, and a nationwide series of exhibitions to establish classical handloom design benchmarks.

Handloom

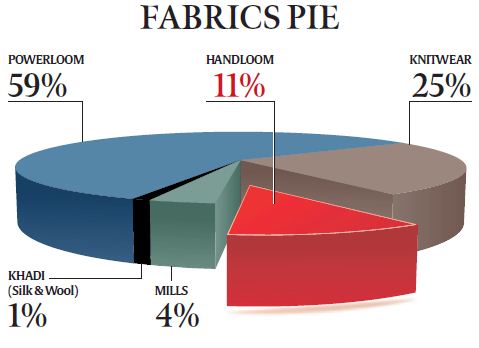

Handloom, or fabric woven by hand, makes up just over a tenth of India’s total fabric production. A spectacular range is created by weavers across the country, from the Madras checks and Kanchipuram weaves of Tamil Nadu to pashmina and shahtoosh of J&K, from the tie-and-dyes of Gujarat and Rajasthan to the eri and muga silks of Assam.

Powerloom

Powerloom accounts for nearly 60% of fabrics and, because it is mechanised, works nearly 10 times faster than handloom. Costs differ, but the gap is massive: handloom can cost Rs 500/metre to create, while the same fabric could be woven on a powerloom for Rs 30/metre. Average investment in a powerloom could be Rs 15,000, three times that of handloom. But many handloom motifs and patterns cannot be replicated on powerloom.

The Handloom (Reservation and Articles for Production) Act, 1985, defined handloom as “any loom other than powerloom”, and included 22 items such as pure silk and cotton saris, lungis, dress material, and towels. The list was whittled down to 11 items in the mid 90s. In 2012, a new definition was proposed: “Handloom means any loom other than powerloom; and includes any hybrid loom on which at least one process of weaving require manual intervention or human energy for production.”

Changes in Act

Powerloom associations want the protection for handloom loosened. Association representatives met officials in April to demand saris be removed from the protected category. A month earlier, a memorandum was submitted to the government seeking the removal of both saris and lungis from the list. What if the protection is lifted?

* Powerloom fabric could be passed off as handloom. Already, because the enforcement of the Act is slack, over 70% of fabric sold as khadi and handloom is powerloom.

* Massive job losses will follow. Handloom requires at least six workers from start to finish, including dyeing, starching, spooling, weaving, ironing and tying up loose ends. Powerloom needs one worker to operate the loom.

* As the industry becomes unremunerative, centuries-old technique and skills could be lost permanently. India as a whole will lose a global USP.

* A negative environmental impact will follow the wider spread of the powerloom. Handloom is sustainable, with a small carbon footprint.

What can be done?

What can be done?

This is what some experts say.

Ritu Sethi, chairperson, Craft Revival Trust: Have separate policies for powerloom and handloom, ensuring that powerloom policy does not cannibalise handloom. Handloom is the second largest industry after agriculture, giving millions direct and indirect employment, and deserves its own ministry.

Maqbool Hassan, master weaver, Varanasi: Have a handloom mark like the gold hallmark to certify authenticity.

Jayati Ghosh, economist: Give handloom weavers access to markets, knowledge, credit. Get textile experts on board as decision-makers.

Deepika Govind, fashion designer: Teach weaving in schools to instil pride in students in urban areas and give a sense of purpose to weavers. Increase market connect for weavers from remote areas.

Laila Tyabji, founder, Dastkar: Government should invest in pre-loom and post-loom stages to ensure handloom weavers get finance, timely raw material and market access. Don’t concentrate only on design and promotion.

http://www.thehindu.com/todays-paper/tp-national/tp-kerala/bringing-weav...

KANNUR: New types of jacquard handloom that are easier to operate than the traditional ones, an improved type of pit-loom that gives uniform texture to fabric and a host of new ways of weaving and pre-loom processing are among the exhibits on display at an exhibition here primarily intended for weavers in the area.

The Appropriate Technology Exhibition that began here on Friday is the 68th such event to be organised by the National Handloom Development Corporation (NHDC). The NHDC organises such exhibitions in different parts of the country in association with the Development Commissioner of Handloom in New Delhi. The exhibition was inaugurated by District Collector Ishita Roy here on Friday.

Dissemination of the latest technical innovations in handloom weaving and processing among the weaving community is the main objective of the exhibition being held at the Municipal High School here. Various organisations and manufacturers in the handloom sector are participating in the expo.

Aim

“Our aim is to introduce appropriate technology to weavers directly so that they will be able to diversify the existing production procedures for improving the quality and productivity and thereby, their earnings,” said NHDC Regional Manager O. Bhaskaran.

Research organisations such as the Weavers Service Centres from Salem, Vijayawada and here, Indian Institute of Handloom Technology, Salem, and the Institute of Handloom Textile Technology at Thottada here were participating in the exhibition. Private engineering organisations that had made new technologies for handloom processing, weaving and pre-loom processing are also exhibiting their products. Dyes and chemicals manufacturers participating in the exhibition introduced to the weavers new methods of processing as per the demands of domestic as well as export market, while cotton yarn manufacturers showed them latest innovations made on cotton yarn.

Increasing efficiency

The exhibition would allow the weavers to know new technologies and processing methods that would increase weaving efficiency and reduce costs of materials such as dyes and yarn, according to NHDC Senior Manager (Commercial) S. Malik.

“Our idea is to let weavers get in touch with actual manufacturers of new technologies and products,” he added.

The exhibition would be held from 9 a.m. to 5 p.m. till February 24, the organisers said.